Winners / Selection Rationale

MAEDA KOSEN CO., LTD. Infrastructure Business

2016 16th Porter Prize Winner Manufacturing and sales of civil engineering construction materials, disaster prevention materials

MAEDA KOSEN (hereafter, Maeda Kosen), a leader in the civil engineering construction materials industry, introduced synthetic fibers to a market in which steel and concrete were the materials predominantly used. Leveraging its superior technology and its broad product line-up, Maeda Kosen responds to requests for consultations from project owners, contractors and construction consultants. In addition, the company proposes solutions to the various stakeholders of construction projects. Also, Maeda Kosen provides after-sales service through its nationwide sales network.

Maeda Kosen is a manufacturer and supplier of various materials for civil engineering construction. Such materials include weather-resistant large-size sandbags used to construct temporary roads in the rebuilding of roads that have collapsed during a natural disaster; net bags made of recycled fibers and used as footwear covers; light and strong fiber mesh sheets used in recovery work on collapsed embankments, to mitigate soil erosion and reinforcement; rockfall protection nets made of high-strength, high-elasticity fibers that are enmeshed in a three-dimensional way; and landscape improvement materials like fences and benches made of recycled plastics, for use in national parks.

Maeda Kosen is a manufacturer and supplier of various materials for civil engineering construction. Such materials include weather-resistant large-size sandbags used to construct temporary roads in the rebuilding of roads that have collapsed during a natural disaster; net bags made of recycled fibers and used as footwear covers; light and strong fiber mesh sheets used in recovery work on collapsed embankments, to mitigate soil erosion and reinforcement; rockfall protection nets made of high-strength, high-elasticity fibers that are enmeshed in a three-dimensional way; and landscape improvement materials like fences and benches made of recycled plastics, for use in national parks.

General features of the civil engineering materials market

The general value chain for civil engineering materials being sold in the market is described as follows: Taking into account the unique requirements of a specific civil engineering construction site project, a construction materials manufacturer will put together a technical proposal and submit this to the construction companies and construction consulting companies involved in the project. After a technical proposal has been accepted a purchase order for the construction materials will be placed. (However, technical proposals are rarely required for materials that are conventional commodities). In some cases, the value chain goes through intermediary agents, who are responsible for delivering the proposal to the construction companies and consulting companies. In addition to the construction companies and consulting companies, another important stakeholder is the owner of the construction site. Owners of civil engineering construction sites are usually: 1) the national government; 2) local governments; and 3) private companies. Installation work will be done by the contracted contractor, but a shortage of skilled manpower, caused by the aging workforce, is usually an issue.

In the case of most public works projects, some kind of certification verifying the quality of construction materials and methods and approval by the relevant authorities will be required. In addition to this certification, materials and methods have to be individually approved, and the consent of all parties (the project owner, construction consultant companies, and construction companies) must be acquired before the materials and methods in question can be selected for use as a construction material for a public works construction project at a specific construction site. This process involves much time, effort, complicated procedures, and manpower. For this reason, many manufacturers of civil engineering construction materials outsource the preparation of these technical proposals to intermediacy agents.

The national budget for public works, which peaked at 9,745 billion yen in 1997, has been declining ever since. In 2016, the public works budget was 5,934 billion yen (6.2% of the entire national budget of 96,722 billion yen). Budget allocation priorities have shifted increasingly from the construction of new roads to maintenance projects (i.e. improving the earthquake resistance of road embankments and bridges) and reinforcement projects (soft ground and riverbank reinforcement).

Japanese companies have gained world-leading prowess in civil engineering technologies as a result of having dealt with various types of disasters. These technologies have gained worldwide recognition for meeting the extremely high technical standards that are characteristic of public works projects. Thus, Japanese companies are expected to extend to developing countries both technical cooperation and business development support, to help these countries devise countermeasures for flooding and other natural disasters.

Unique Value Proposition

Maeda Kosen has developed civil engineering construction materials that are light and strong, with superior workability. The company has created such innovative materials by applying both its proprietary fiber and textile processing technology and its resin molding technology (i.e. combining resin with heat-resistant strong aramid fibers and carbon fibers). Maeda Kosen also has developed a variety of new methods for application in the civil engineering field. Such applications include: 1) infrastructure facility maintenance and repair; 2) the prevention and mitigation of disasters; and 3) environmental protection and environmental remediation work. Maeda Kosen proposes technical solutions, methods and materials to project owners (i.e. the national and local governments), construction companies, construction consulting companies, and intermediacy agents. Maeda Kosen is a specialist in materials and methods for drainage, ground reinforcement, riverbank protection, oil absorbent fences for oil spills, and landscape improvement materials. Maeda Kosen's sales engineers make the structural calculations and design proposals themselves. The company's sales engineers have been assigned to work sites all around the country. Equipped with extensive knowledge of materials, methods and construction sites, these sales engineers undertake the drafting of individual technology proposals for each particular project.

Maeda Kosen has a broad product line-up, and offers various options for the industry. The company's product line-up consists of both unique products that are manufactured in-house and general items sourced from outside manufacturers. By leveraging its broad product line-up, Maeda Kosen is able to develop proposals that are "a total package of solutions" for its customers.

For example, in the case of a new road construction project, when Maeda Kosen submits a design for soft soil reinforcement of land on which a new road will be built, the company will simultaneously offer a proposal on vegetation materials for the road's embankment slope. Multiple proposals are submitted together as a total package of solutions for a specific construction site. In the case of a project that requires a combination of highly technical solutions to address multiple issues, such a comprehensive approach would not be possible if the project owner were to tackle all the individual parts of a project. By leveraging the company's expertise and capabilities, Maeda Kosen is able to provide its customers with distinctive added value. This same kind of added value could not be provided if a sales approach that focused on a single product were used.

Maeda Kosen also provides installation instruction services at the construction site, assisting with technical details. This instruction is given to construction companies when they start the actual installation work. After the completion of construction, the Maeda Kosen sales engineer working in closest proximity to the construction site is given the responsibility of profiling the project, filing an installation record, and keeping the records for maintenance purposes. (Those records are kept for a ten- to twenty-year period.) Follow-up visits are made to the construction site because on-going after-sales services are provided whenever such services are necessary. Maeda Kosen's sales engineers are often aware of the details of all major civil works projects in the region, regardless of whether Maeda Kosen was involved or not. These sales engineers also function as a great "disaster recovery support force" that helps local governments in times of disaster by: 1) developing plans for reinforcement work; 2) diagnosing the damage done by natural disasters; and 3) developing and implementing recovery plans following natural disasters.

Maeda Kosen keeps inventories at its major logistics centers in many regions of Japan. Having a stockpile of inventory stored nearby enables the company to quickly implement disaster response and recovery measures in the case of an emergency.

Through these activities, Maeda Kosen differentiates itself from its competitors and delivers highly value-added services that other manufacturers are not easily able to provide.

Maeda Kosen has a broad product line-up, and offers various options for the industry. The company's product line-up consists of both unique products that are manufactured in-house and general items sourced from outside manufacturers. By leveraging its broad product line-up, Maeda Kosen is able to develop proposals that are "a total package of solutions" for its customers.

For example, in the case of a new road construction project, when Maeda Kosen submits a design for soft soil reinforcement of land on which a new road will be built, the company will simultaneously offer a proposal on vegetation materials for the road's embankment slope. Multiple proposals are submitted together as a total package of solutions for a specific construction site. In the case of a project that requires a combination of highly technical solutions to address multiple issues, such a comprehensive approach would not be possible if the project owner were to tackle all the individual parts of a project. By leveraging the company's expertise and capabilities, Maeda Kosen is able to provide its customers with distinctive added value. This same kind of added value could not be provided if a sales approach that focused on a single product were used.

Maeda Kosen also provides installation instruction services at the construction site, assisting with technical details. This instruction is given to construction companies when they start the actual installation work. After the completion of construction, the Maeda Kosen sales engineer working in closest proximity to the construction site is given the responsibility of profiling the project, filing an installation record, and keeping the records for maintenance purposes. (Those records are kept for a ten- to twenty-year period.) Follow-up visits are made to the construction site because on-going after-sales services are provided whenever such services are necessary. Maeda Kosen's sales engineers are often aware of the details of all major civil works projects in the region, regardless of whether Maeda Kosen was involved or not. These sales engineers also function as a great "disaster recovery support force" that helps local governments in times of disaster by: 1) developing plans for reinforcement work; 2) diagnosing the damage done by natural disasters; and 3) developing and implementing recovery plans following natural disasters.

Maeda Kosen keeps inventories at its major logistics centers in many regions of Japan. Having a stockpile of inventory stored nearby enables the company to quickly implement disaster response and recovery measures in the case of an emergency.

Through these activities, Maeda Kosen differentiates itself from its competitors and delivers highly value-added services that other manufacturers are not easily able to provide.

Unique Value Chain

Maeda Kosen is also unique in its value chain, especially with regard to sales activities. Maeda Kosen's sales engineers are in charge of all the processes, and they deal with all the stakeholders. They are equipped with a deep and broad knowledge of engineering products and methods, and are capable of making structural calculations. Moreover, they are deeply entrenched in the region, and understand the history of every major public works construction project in the region.

R&D

Maeda Kosen's core competencies are in geosynthetic technology applied to civil engineering applications, fiber processing technology, manufacturing technology of non-woven fabric, resin molding technology, new composite-materials development technology, civil engineering technology, and measurement and analysis technology. Maeda Kosen undertakes research in-house on these core technologies, but also actively conducts joint research with universities. In addition, the company frequently presents research papers at international academic conferences, which has led to collaboration on joint development projects with overseas companies and public organizations, particularly in the area of disaster prevention.

New product development is undertaken by six Marketing and Development Departments. Each of these six divisions is responsible for one of the following areas: 1) Ground reinforcement and drainage; 2) facility maintenance; 3) landscape improvement materials; 4) water environment maintenance; 5) slope disaster prevention; and 6) forest preservation. When combined, these six divisions can cover all materials for civil engineering applications in every area of specialization. The six divisions know what the other divisions are doing, which helps each division to develop new products and to apply products from one area to another. R&D staff members in charge of product development collect information at academic conferences. They also receive updates about customer needs at monthly sales meetings. R&D staff and sales offices attend product briefing sessions in these monthly sales meetings and exchange information. Sales engineers are informed about new products at product briefing sessions organized by a member of the Marketing and Development Departments every two weeks. Sales engineers become familiar with the new products, learn how these products can be used at construction sites, and deepen their understanding of the affinity between these new products and other existing materials.

Products that are being used for new applications or that offer new features often require certificates of authorization (i.e. manufacturing and sales licenses) issued by public organizations, such as the Public Works Research Center (PWRC), to demonstrate compliance with the strictest quality standards. Maeda Kosen undertakes product development, conducts numerous field trials, and proposes standards to encourage the adoption of new technologies. For example, when Maeda Kosen introduced weather-resistant large-size sandbags that offered radically improved weather resistance, this was considered to be a new product that had to be examined and certified by an official authority.

Manufacturing

Maeda Kosen does not restrict production to in-house manufacturing. It selects the best resources and will hire outside contract manufacturers regardless of whether their factories are located in Japan or overseas. Maeda Kosen matches products to the most suitable manufacturing plant (or else sources those products from somewhere within the supply chain), and creates its own production map for each product category.

Sales

Maeda Kosen's sales engineers are in charge of drafting technical proposals, offering on-site instruction for technical installation, and providing post-construction after-sales services. The technical proposals prepared by Maeda Kosen feature a high degree of completion, and include construction calculations. These proposals are submitted to project owners (i.e. government administration offices) and construction consultants. After the proposals have been accepted by the construction consultants, Maeda Kosen's sales engineers approach the construction companies directly. The sales engineers make sales calls, deliver construction materials, and provide instruction on technical installation and give guidance whenever necessary. The sales engineers are also responsible for after-sales services, which include checking the work after the completion of construction. Sales engineers must record the details for each part of the project, and keep track of this information. Maeda Kosen's sales engineers cover all the prefectures, and are rarely transferred to different regions. This enables them to develop an extensive knowledge regarding the long history of civil works projects in their area.

Outward bound logistics

In order to provide swift action for disaster recovery, Maeda Kosen has established logistics centers throughout Japan in collaboration with local logistics companies. At these centers, Maeda Kosen keeps inventories of particular products that will be necessary for disaster response and recovery, based on knowledge developed through many years of involvement in that field.

Post-construction services

For ground reinforcement projects, Maeda Kosen creates and maintains records for each project, and monitors the situation according to its importance. In the case of sites that are not registered on a map, which is often the case when the site is deep in the mountains, Maeda Kosen keeps records using the latitude and longitude readings taken from a GPS system. This way, the company can keep track of the site even after the person in charge has left. Maeda Kosen embeds optical fibers into the ground to monitor the soundness of major sites by periodically collecting data on ground strain. This enables Maeda Kosen to notice any changes and take the necessary countermeasures. Preventive reinforcement efforts result in increased safety for people, as well as a reduction in the cost of public works projects.

Human Resources Management

In order to cultivate a team of sales engineers with deep and broad expertise in the company's products and methods, professionals who can create meticulous proposals that have been customized for each individual construction site, Maeda Kosen assigns each new sales engineer to a variety of constructions sites that include roads, rivers, and ports, and continues dispatching them to a large number of sites over time. The company also organizes in-house competitions. Participants are required to submit proposals containing solutions developed for fictional cases, and conduct study groups to review successful proposals. The company encourages its sales engineers to write and publish research papers in academic journals in the field of civil engineering. The company also encourages its sales engineers to acquire additional professional qualifications as a consulting engineer, an architect, or a first-class civil engineering works execution managing engineer, for example.

General Management

Maeda Kosen identifies its basic philosophy of management as follows: "Maintaining good relationships between people is the foundation for everything, and is our goal." Accordingly, this basic philosophy makes the company's approach a customer-centric one. The company raises awareness among its people about how Maeda Kosen's products "protect the homeland." The company puts a priority on investing in the post-construction monitoring of the work that has been done and providing follow-up services. The company's CEO, Yukitoshi Maeda, places great emphasis on the corporate message: "Maeda Kosen is a company that synthesizes." He realizes the importance of information-sharing among the different technological areas and product categories, as well as the crucial role of information sharing in the post-merger integration process.

Post-Merger Integration (PMI)

Maeda Kosen has acquired seven companies and business units since 2000, in order to aggressively diversify into different technological areas. The Marketing and Development Division, and the Corporate Planning Office have staff members who are in charge of integrating technology and strategy. These individuals understand all the technologies that Maeda Kosen possesses. They develop R&D plans, and identify which technologies and which companies should be acquired through M&As.

After the acquisition, executives of Maeda Kosen make frequent visits to the acquired company, and communicate directly with the employees there in order to calm them, reassure them, and convince them not to resign. The secondment of staff to the acquired company is done to foster a mutual understanding of the details of each company's business operations. This practice is consistent with the company's basic philosophy, "Maintaining good relationships between people is the foundation for everything, and this is our goal."

Soon after the acquisition of a company, a study group is organized to help Maeda Kosen's sales engineers understand the acquired company's technologies and products, which will quickly be added to Maeda Kosen's offerings. After the synergies with an acquired company have been achieved, from time to time Maeda Kosen will absorb that business unit and make it an internal division or department.

R&D

Maeda Kosen's core competencies are in geosynthetic technology applied to civil engineering applications, fiber processing technology, manufacturing technology of non-woven fabric, resin molding technology, new composite-materials development technology, civil engineering technology, and measurement and analysis technology. Maeda Kosen undertakes research in-house on these core technologies, but also actively conducts joint research with universities. In addition, the company frequently presents research papers at international academic conferences, which has led to collaboration on joint development projects with overseas companies and public organizations, particularly in the area of disaster prevention.

New product development is undertaken by six Marketing and Development Departments. Each of these six divisions is responsible for one of the following areas: 1) Ground reinforcement and drainage; 2) facility maintenance; 3) landscape improvement materials; 4) water environment maintenance; 5) slope disaster prevention; and 6) forest preservation. When combined, these six divisions can cover all materials for civil engineering applications in every area of specialization. The six divisions know what the other divisions are doing, which helps each division to develop new products and to apply products from one area to another. R&D staff members in charge of product development collect information at academic conferences. They also receive updates about customer needs at monthly sales meetings. R&D staff and sales offices attend product briefing sessions in these monthly sales meetings and exchange information. Sales engineers are informed about new products at product briefing sessions organized by a member of the Marketing and Development Departments every two weeks. Sales engineers become familiar with the new products, learn how these products can be used at construction sites, and deepen their understanding of the affinity between these new products and other existing materials.

Products that are being used for new applications or that offer new features often require certificates of authorization (i.e. manufacturing and sales licenses) issued by public organizations, such as the Public Works Research Center (PWRC), to demonstrate compliance with the strictest quality standards. Maeda Kosen undertakes product development, conducts numerous field trials, and proposes standards to encourage the adoption of new technologies. For example, when Maeda Kosen introduced weather-resistant large-size sandbags that offered radically improved weather resistance, this was considered to be a new product that had to be examined and certified by an official authority.

Manufacturing

Maeda Kosen does not restrict production to in-house manufacturing. It selects the best resources and will hire outside contract manufacturers regardless of whether their factories are located in Japan or overseas. Maeda Kosen matches products to the most suitable manufacturing plant (or else sources those products from somewhere within the supply chain), and creates its own production map for each product category.

Sales

Maeda Kosen's sales engineers are in charge of drafting technical proposals, offering on-site instruction for technical installation, and providing post-construction after-sales services. The technical proposals prepared by Maeda Kosen feature a high degree of completion, and include construction calculations. These proposals are submitted to project owners (i.e. government administration offices) and construction consultants. After the proposals have been accepted by the construction consultants, Maeda Kosen's sales engineers approach the construction companies directly. The sales engineers make sales calls, deliver construction materials, and provide instruction on technical installation and give guidance whenever necessary. The sales engineers are also responsible for after-sales services, which include checking the work after the completion of construction. Sales engineers must record the details for each part of the project, and keep track of this information. Maeda Kosen's sales engineers cover all the prefectures, and are rarely transferred to different regions. This enables them to develop an extensive knowledge regarding the long history of civil works projects in their area.

Outward bound logistics

In order to provide swift action for disaster recovery, Maeda Kosen has established logistics centers throughout Japan in collaboration with local logistics companies. At these centers, Maeda Kosen keeps inventories of particular products that will be necessary for disaster response and recovery, based on knowledge developed through many years of involvement in that field.

Post-construction services

For ground reinforcement projects, Maeda Kosen creates and maintains records for each project, and monitors the situation according to its importance. In the case of sites that are not registered on a map, which is often the case when the site is deep in the mountains, Maeda Kosen keeps records using the latitude and longitude readings taken from a GPS system. This way, the company can keep track of the site even after the person in charge has left. Maeda Kosen embeds optical fibers into the ground to monitor the soundness of major sites by periodically collecting data on ground strain. This enables Maeda Kosen to notice any changes and take the necessary countermeasures. Preventive reinforcement efforts result in increased safety for people, as well as a reduction in the cost of public works projects.

Human Resources Management

In order to cultivate a team of sales engineers with deep and broad expertise in the company's products and methods, professionals who can create meticulous proposals that have been customized for each individual construction site, Maeda Kosen assigns each new sales engineer to a variety of constructions sites that include roads, rivers, and ports, and continues dispatching them to a large number of sites over time. The company also organizes in-house competitions. Participants are required to submit proposals containing solutions developed for fictional cases, and conduct study groups to review successful proposals. The company encourages its sales engineers to write and publish research papers in academic journals in the field of civil engineering. The company also encourages its sales engineers to acquire additional professional qualifications as a consulting engineer, an architect, or a first-class civil engineering works execution managing engineer, for example.

General Management

Maeda Kosen identifies its basic philosophy of management as follows: "Maintaining good relationships between people is the foundation for everything, and is our goal." Accordingly, this basic philosophy makes the company's approach a customer-centric one. The company raises awareness among its people about how Maeda Kosen's products "protect the homeland." The company puts a priority on investing in the post-construction monitoring of the work that has been done and providing follow-up services. The company's CEO, Yukitoshi Maeda, places great emphasis on the corporate message: "Maeda Kosen is a company that synthesizes." He realizes the importance of information-sharing among the different technological areas and product categories, as well as the crucial role of information sharing in the post-merger integration process.

Post-Merger Integration (PMI)

Maeda Kosen has acquired seven companies and business units since 2000, in order to aggressively diversify into different technological areas. The Marketing and Development Division, and the Corporate Planning Office have staff members who are in charge of integrating technology and strategy. These individuals understand all the technologies that Maeda Kosen possesses. They develop R&D plans, and identify which technologies and which companies should be acquired through M&As.

After the acquisition, executives of Maeda Kosen make frequent visits to the acquired company, and communicate directly with the employees there in order to calm them, reassure them, and convince them not to resign. The secondment of staff to the acquired company is done to foster a mutual understanding of the details of each company's business operations. This practice is consistent with the company's basic philosophy, "Maintaining good relationships between people is the foundation for everything, and this is our goal."

Soon after the acquisition of a company, a study group is organized to help Maeda Kosen's sales engineers understand the acquired company's technologies and products, which will quickly be added to Maeda Kosen's offerings. After the synergies with an acquired company have been achieved, from time to time Maeda Kosen will absorb that business unit and make it an internal division or department.

Fit among Activities

The activities of Maeda Kosen's Infrastructure Division center around two cores. The first core is comprised of: 1) broad technologies, and the synthesizing of these technologies; and 2) proposals that offer a total package of solutions. The technologies enable the provision of solutions as a total package, and the combination of these products and services creates high value-added. The second core entails on-going customer service, and includes the monitoring of sites after the completion of construction. Customers trust the company because of its long-term commitment to post-construction project monitoring. This, in turn, contributes to the competitiveness of Maeda Kosen's proposals. These core activities are delivered by various divisions and offices within the company. These include the Marketing and Development Division and the Corporate Planning Office, which coordinate the development of business plans that include technology strategy; six Marketing and Development Departments, which undertake research; and the Sales Division, which handles communications with clients and the development of proposals, and provides technical installation instruction and post-construction services. (Please refer to Maeda Kosen Co., Ltd., Infrastructure Division's activity system map, which appears at the end of this report.)

Innovation that Enabled Strategy

- Has applied fiber-and textile-related technology to civil engineering construction materials.

- Creates and maintains detailed records on major construction sites where the company's materials have been installed.

- Encourages sales engineer employees to become very firmly rooted in their own region of Japan.

- Uses ground reinforcement materials with embedded optical fibers, which enable the periodical monitoring of soil deformation.

Trade-offs

- Does not target a growth in sales volume as its first priority. Maeda Kosen emphasizes profitability over the amount of profit.

- Chooses customers who put greater value on high-value-added products and solutions.

- Does not compete on price.

- Does not limit itself to in-house developed technologies. Aggressively pursues mergers and acquisitions, as well as alliances with universities and other companies.

- Does not assign the preparation of proposals, sales activities and post-construction services to different personnel. One sales engineer is responsible for handling all of these activities. Involvement in all of these activities helps an individual sales engineer to develop a deeper understanding of the company's products, methods, and work sites. This also helps individuals to develop a sense of ownership for a project.

- Does not frequently rotate sales engineers.

- Does not avoid the costs involved in the provision of post-construction services. Maeda Kosen believes that the provision of post-construction services helps the company to develop customized proposals that will effectively resolve the construction site's specific issues.

- Does not avoid the risks involved in mergers and acquisitions. Maeda Kosen believes that if there is no risk, there is no innovation. The company focuses its efforts on solving the issues that underlie the risk.

- Does not rely on internally developed people. Maeda Kosen aggressively hires people from other companies if that person has good problem-solving abilities and is a good fit for the job.

Consistency of Strategy over Time

Maeda Kosen's core consistency of its competitive strategy is technology leadership based on unique technology and the quality of its technical proposals. The company's technology leadership has been further enhanced by the broadening of its product line-up through mergers and acquisitions (M&As) and the improvement of capabilities to enable the company to synthesize different technologies. Another core consistency is Maeda Kosen's commitment to providing on-going services that continue long after the completion of a construction project. This commitment to the long-term provision of on-going services is supported by the creation and maintenance of records for each construction site, and by the cultivation of a team of sales engineers who have developed strong roots in each region.

Maeda Weaving Factory, the predecessor of Maeda Kosen, was established in 1918, so Maeda Kosen will be celebrating its 100-year anniversary in 2018. Maeda Kosen's infrastructure business was started by the current CEO, Yukitoshi Maeda, in 1972, when he used synthetic fibers to develop subterranean drainage materials for road construction. During Japan's period of rapid economic growth in the 1970s, the Japanese government invested aggressively in public works projects and built roads, which created the demand for drainage materials. This is how Maeda Kosen was able to establish itself as a pioneer of geosynthetics (fibers applied in public works construction projects).

In the 1980s, Maeda Kosen introduced low-elasticity fiber materials with superior shock resistance for use in the reinforcement of embankments. These materials, manufactured in-house using extremely rigid aramid fibers, have been used to reinforce vertical walls and embankments with steep slopes during the construction of roads and dams. This developed into the second product area for Maeda Kosen.

In the 1990s, facilities made of concrete that had been built in the 1970s became old and weak. Maeda Kosen introduced carbon or aramid fiber sheets that are wrapped around the piers of bridges and the pillars of buildings to prevent the falling of masonry and provide the reinforcement of concrete against earthquakes. This new product enabled Maeda Kosen to enter the field of maintenance and repair for public works projects.

After the year 2000, frequent natural disasters evoked the enhancement of safety and extended the service life of facilities. Maeda Kosen introduced new products to satisfy new technological standards through new product development and the improvement of existing products. In the mid- 2000s, Maeda Kosen assigned a sales engineer to each prefecture , and started delivering more detailed customer service, which included the keeping of records for each major construction site. As fewer new roads were being built, demand for reinforcement materials for embankments began to decrease. Recognizing this contraction of its major product market, Maeda Kosen started to diversify into civil engineering areas other than road construction, and also pursued overseas business expansion. The company acquired seven companies and business units after 2000, and entered into new areas like marine applications (fences for preventing the spread of pollution and oil-absorbent fences for oil spills), landscape improvement materials (synthetic wood slats and planks for use in fences), forest preservation materials (vegetation sheets, products made of timber from forest thinning, riverside reinforcement products), and agricultural materials.

After 2010, Maeda Kosen put more effort into overseas expansion. In 2011, the company commenced production in Vietnam of landscape improvement materials (like synthetic wood) and oil fences that prevent oil spills from spreading. At the same time, the company began to build a sales network for infrastructure-related markets in Southeast Asian countries, and started selling its products to public sector entities, especially for applications relating to natural disasters, and to the private sector.

Maeda Weaving Factory, the predecessor of Maeda Kosen, was established in 1918, so Maeda Kosen will be celebrating its 100-year anniversary in 2018. Maeda Kosen's infrastructure business was started by the current CEO, Yukitoshi Maeda, in 1972, when he used synthetic fibers to develop subterranean drainage materials for road construction. During Japan's period of rapid economic growth in the 1970s, the Japanese government invested aggressively in public works projects and built roads, which created the demand for drainage materials. This is how Maeda Kosen was able to establish itself as a pioneer of geosynthetics (fibers applied in public works construction projects).

In the 1980s, Maeda Kosen introduced low-elasticity fiber materials with superior shock resistance for use in the reinforcement of embankments. These materials, manufactured in-house using extremely rigid aramid fibers, have been used to reinforce vertical walls and embankments with steep slopes during the construction of roads and dams. This developed into the second product area for Maeda Kosen.

In the 1990s, facilities made of concrete that had been built in the 1970s became old and weak. Maeda Kosen introduced carbon or aramid fiber sheets that are wrapped around the piers of bridges and the pillars of buildings to prevent the falling of masonry and provide the reinforcement of concrete against earthquakes. This new product enabled Maeda Kosen to enter the field of maintenance and repair for public works projects.

After the year 2000, frequent natural disasters evoked the enhancement of safety and extended the service life of facilities. Maeda Kosen introduced new products to satisfy new technological standards through new product development and the improvement of existing products. In the mid- 2000s, Maeda Kosen assigned a sales engineer to each prefecture , and started delivering more detailed customer service, which included the keeping of records for each major construction site. As fewer new roads were being built, demand for reinforcement materials for embankments began to decrease. Recognizing this contraction of its major product market, Maeda Kosen started to diversify into civil engineering areas other than road construction, and also pursued overseas business expansion. The company acquired seven companies and business units after 2000, and entered into new areas like marine applications (fences for preventing the spread of pollution and oil-absorbent fences for oil spills), landscape improvement materials (synthetic wood slats and planks for use in fences), forest preservation materials (vegetation sheets, products made of timber from forest thinning, riverside reinforcement products), and agricultural materials.

After 2010, Maeda Kosen put more effort into overseas expansion. In 2011, the company commenced production in Vietnam of landscape improvement materials (like synthetic wood) and oil fences that prevent oil spills from spreading. At the same time, the company began to build a sales network for infrastructure-related markets in Southeast Asian countries, and started selling its products to public sector entities, especially for applications relating to natural disasters, and to the private sector.

Profitability

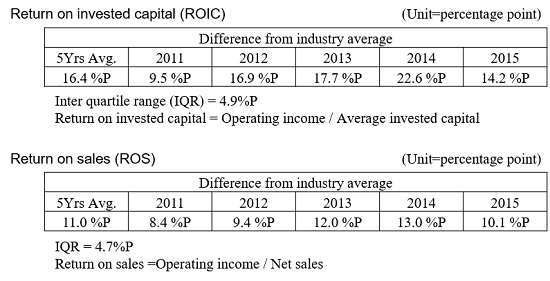

Both the five-year average of return on invested capital and return on sales exceed the industry average. (Profitability analysis was conducted by PwC Japan.)

Activity System Map

Winners PDF

- 2016 Porter Prize Winners PDF (All of the award company in this year are published. )