Winners / Selection Rationale

YKK CORPORATION Fastening Products Group

2014 14th Porter Prize Winner Fastener manufacturer and distributor

The global leader in the fastening industry with a unique value chain.

YKK CORPORATION Fastening Products Group (hereafter, YKK) is the global leader in the fastening industry, with a focus on the middle and high end of the market for fastening products in the fashion, sports apparel and industrial materials markets. No other company can compete against YKK in the high function and high fashion areas. YKK is also the technological leader in fasteners, providing fasteners for space suits, for example.

YKK CORPORATION Fastening Products Group (hereafter, YKK) is the global leader in the fastening industry, with a focus on the middle and high end of the market for fastening products in the fashion, sports apparel and industrial materials markets. No other company can compete against YKK in the high function and high fashion areas. YKK is also the technological leader in fasteners, providing fasteners for space suits, for example.It has operations in 70 countries and regions, to be closer to customers, and customizes its products in order to accommodate a wide variety of customer needs. Extensive vertical integration results in high-performance products, stable quality, and lower costs. Such factors are critical in this business, because although a zipper may be a low-cost component of apparel products, one defective product can ruin a customer's trust in the apparel brand. People might be able to wear an article of clothing even if some stiches are not straight, but when the zipper is broken, the item is useless. For bag manufacturers, the zipper is one of the most critical parts of the bag, because it is one of the few parts that might break.

Unique Value Proposition

YKK has the broadest product line and serves the widest range of customers. It has established a competitive advantage in each segment, except in the low end of the market. In general, YKK, which offers an extensive lineup of high-quality products, is known for its stable and responsible supply, as well as its capabilities for developing new models that are customized to meet specific customer needs.

The market for the fastening business is broad, and YKK has been successfully responding to customer requests for product customization needs of various customers through one-to-one marketing. Customer needs vary from segment to segment, and even within a segment certain customers require unique fastening solutions. The luxury fashion segment is primarily located in Europe, and these customers require a heightened sensitivity toward fashion and extravagance. Sports apparel customers, located mainly in North America and Europe, place an emphasis on high-function products. Customers who provide sewing services to the fast fashion business are located in China, Southeast Asia and South Asia. They require a large variety of fasteners, to be offered at relatively low prices. Customers (apparel makers) serving local demand for apparel products in emerging markets look for even lower prices. Some of these customers are local, while others are global. In the case of the fast fashion business, the apparel companies are located in Europe but the sewing companies (who are the direct customers of YKK) are located in Asia. In the industrial materials segment, the customer base is extremely diversified. Customers in this segment include automobile seat manufacturers, for example. Special applications for YKK fasteners include use in space suits (pressurization suits), thermal curtains in the H-IIA Rocket, drainageways for the Akashi-Kaikyo Bridge, milk tanks for bulk transportation, and fishing nets, to name a few.

YKK's product line is made up of both standardized and customized products, and the company's stock keeping unit (SKU) is huge, totaling several tens of thousands of items.

The market for the fastening business is broad, and YKK has been successfully responding to customer requests for product customization needs of various customers through one-to-one marketing. Customer needs vary from segment to segment, and even within a segment certain customers require unique fastening solutions. The luxury fashion segment is primarily located in Europe, and these customers require a heightened sensitivity toward fashion and extravagance. Sports apparel customers, located mainly in North America and Europe, place an emphasis on high-function products. Customers who provide sewing services to the fast fashion business are located in China, Southeast Asia and South Asia. They require a large variety of fasteners, to be offered at relatively low prices. Customers (apparel makers) serving local demand for apparel products in emerging markets look for even lower prices. Some of these customers are local, while others are global. In the case of the fast fashion business, the apparel companies are located in Europe but the sewing companies (who are the direct customers of YKK) are located in Asia. In the industrial materials segment, the customer base is extremely diversified. Customers in this segment include automobile seat manufacturers, for example. Special applications for YKK fasteners include use in space suits (pressurization suits), thermal curtains in the H-IIA Rocket, drainageways for the Akashi-Kaikyo Bridge, milk tanks for bulk transportation, and fishing nets, to name a few.

YKK's product line is made up of both standardized and customized products, and the company's stock keeping unit (SKU) is huge, totaling several tens of thousands of items.

Unique Value Chain

YKK's value chain is unique in its vertical integration. YKK internally develops and manufactures materials, machinery and fasteners in order to maintain the best quality in the industry. The company's research includes material technologies, in such areas as metals, resins and fibers.

Manufacturing:

The shorter product life cycle of apparel products has prompted the company to set up extensive manufacturing operations in numerous countries, to be closer to overseas customers and to ensure that all customers receive the same high-quality products. (YKK has factories in 39 countries and regions.)

YKK develops its own manufacturing machinery, and automates most of the production process. It also has flexible manufacturing capabilities. The Machinery & Engineering Group, which is in charge of manufacturing technology and machinery, supplies manufacturing technology and machinery to YKK factories all over the world.

Research & Development:

The company has established five technical centers in Japan, the U.S., Italy, Taiwan and Indonesia, and these five technical centers all undertake long-term research. YKK has 15 product development offices in overseas locations, and the company plans to add five more, bringing the total to 20 at the end of March 2015 (the fiscal 2014 year-end). New offices are being opened in Turkey, India, Bangladesh, Vietnam, and Brazil to respond to the transfer of sewn product manufacturing operations from China to ASEAN and South Asian countries. At these overseas centers, YKK undertakes the development of new products together with its local customers. A development team in Europe focuses on luxury bags and luxury apparel, and YKK's customer list includes many luxury brands. In North America, the company is developing fasteners that fix fabric covers to automobile seats, as well as the machinery for attaching those fasteners to automobile seat covers (the company leases this machinery to auto seat manufacturers). In Shanghai, a specialized development team serves fast fashion customers, who often require a large variety of fastening products, reasonable prices, and short lead times (i.e. delivery within five days after an order has been placed). The R&D Center in Japan develops core technologies and also functions as the headquarters for all of YKK's R&D facilities worldwide.

Marketing & Sales:

YKK customizes its products, responding to specific customer requests. The company operates sales offices and manufacturing plants in 70 countries and regions worldwide. By working closer to its overseas customers, the company is able to provide a quicker response.

YKK's global accounts include a company that has more than 2,000 sewing factories in 60 countries. YKK's Global Marketing Group (GMG) has its main office in Hong Kong, and several overseas bases. GMG handles 50 apparel companies with global accounts and 700 global sewing contractors. GMG allocates designated sales staff to each customer, and ensures that customers are supplied the same product and the same quality worldwide. GMG communicates with both buyers at

Human resources management:

YKK has started sending Japanese employees to its overseas facilities at a younger age, and has been keeping them there longer (for 10-15 years, or even more than 20 years at some overseas facilities). Employees working overseas are encouraged to "go native" in their assigned countries. This is because the company believes in the importance of on-the-job business experience for its employees. The company calls this practice "yasen no ittoryu" (mastery in the field). YKK simultaneously conducts off-the-job training programs, called "dojo no ittoryu" (mastery at the gymnasium or academy).

General management:

YKK's region-based organizational structure focuses on six regions: 1) North and Central America; 2) South America; 3) Europe, the Middle East, and Africa (EMEA); 4) China; 5) Asia; and 6) Japan. Each region is invested with decision-making power, and this enables the company to accommodate differences in customer needs, which vary from region to region.

YKK's corporate philosophy is: "Cycle of goodness--No one prospers without rendering benefit to others." This means that YKK contributes to the local community and economy as a local entity in the country in which it is operating. In line with this philosophy, the company chooses sites for industrial development that will allow it to contribute to the local economy. The company is committed to reinvesting profits in local operations, rather than repatriating those profits to Japan. In instances where YKK's fastener-related operations in an overseas market prove to be unsustainable due to insufficient profitability, rather than withdraw from that market YKK will establish some other kind of business, to retain its staff and continue providing employment opportunities for local workers. YKK's commitment applies to workers in local areas in Japan too. YKK calls Kurobe City (Toyoma Prefecture), where the company's mother factory and R&D function are located, its "head temple of technology." Over the years, the company has been moving some headquarter functions from Tokyo to Kurobe.

YKK's executives spend many hours discussing with employees the company's philosophy regarding the "Cycle of goodness," its management principle, "YKK seeks corporate value of higher significance," and its core values. A list of YKK core values includes the following: "Do not fear failure, experience builds success," "Create opportunities for employees," "Insist on quality in everything," and "Build trust, transparency and respect." The last one was added under the founder's direction when the first oil crisis erupted in 1973. He declared: "We will never raise prices opportunistically, even if we lose 10 billion yen." The list of trade-offs below illustrates how much the company is guided by its philosophy and core values, which have influenced the formation of its unique competitive strategy.

YKK was founded in 1934, and has remained unlisted for its entire history. This is because the company's founder, Tadao Yoshida, believing that stocks are a certificate of participation in the business, started up an employee stock ownership plan. This policy has been upheld by his successors, and the company's largest shareholders are its employees.

The founder also wanted employee participation in management. He compared YKK to a forest, made up of various kinds of trees (young and old, tall and short), each must live its own life. He wanted YKK to be a vital organization, in which employees can voice their own opinions, regardless of their positions or specialties.

Manufacturing:

The shorter product life cycle of apparel products has prompted the company to set up extensive manufacturing operations in numerous countries, to be closer to overseas customers and to ensure that all customers receive the same high-quality products. (YKK has factories in 39 countries and regions.)

YKK develops its own manufacturing machinery, and automates most of the production process. It also has flexible manufacturing capabilities. The Machinery & Engineering Group, which is in charge of manufacturing technology and machinery, supplies manufacturing technology and machinery to YKK factories all over the world.

Research & Development:

The company has established five technical centers in Japan, the U.S., Italy, Taiwan and Indonesia, and these five technical centers all undertake long-term research. YKK has 15 product development offices in overseas locations, and the company plans to add five more, bringing the total to 20 at the end of March 2015 (the fiscal 2014 year-end). New offices are being opened in Turkey, India, Bangladesh, Vietnam, and Brazil to respond to the transfer of sewn product manufacturing operations from China to ASEAN and South Asian countries. At these overseas centers, YKK undertakes the development of new products together with its local customers. A development team in Europe focuses on luxury bags and luxury apparel, and YKK's customer list includes many luxury brands. In North America, the company is developing fasteners that fix fabric covers to automobile seats, as well as the machinery for attaching those fasteners to automobile seat covers (the company leases this machinery to auto seat manufacturers). In Shanghai, a specialized development team serves fast fashion customers, who often require a large variety of fastening products, reasonable prices, and short lead times (i.e. delivery within five days after an order has been placed). The R&D Center in Japan develops core technologies and also functions as the headquarters for all of YKK's R&D facilities worldwide.

Marketing & Sales:

YKK customizes its products, responding to specific customer requests. The company operates sales offices and manufacturing plants in 70 countries and regions worldwide. By working closer to its overseas customers, the company is able to provide a quicker response.

YKK's global accounts include a company that has more than 2,000 sewing factories in 60 countries. YKK's Global Marketing Group (GMG) has its main office in Hong Kong, and several overseas bases. GMG handles 50 apparel companies with global accounts and 700 global sewing contractors. GMG allocates designated sales staff to each customer, and ensures that customers are supplied the same product and the same quality worldwide. GMG communicates with both buyers at

Human resources management:

YKK has started sending Japanese employees to its overseas facilities at a younger age, and has been keeping them there longer (for 10-15 years, or even more than 20 years at some overseas facilities). Employees working overseas are encouraged to "go native" in their assigned countries. This is because the company believes in the importance of on-the-job business experience for its employees. The company calls this practice "yasen no ittoryu" (mastery in the field). YKK simultaneously conducts off-the-job training programs, called "dojo no ittoryu" (mastery at the gymnasium or academy).

General management:

YKK's region-based organizational structure focuses on six regions: 1) North and Central America; 2) South America; 3) Europe, the Middle East, and Africa (EMEA); 4) China; 5) Asia; and 6) Japan. Each region is invested with decision-making power, and this enables the company to accommodate differences in customer needs, which vary from region to region.

YKK's corporate philosophy is: "Cycle of goodness--No one prospers without rendering benefit to others." This means that YKK contributes to the local community and economy as a local entity in the country in which it is operating. In line with this philosophy, the company chooses sites for industrial development that will allow it to contribute to the local economy. The company is committed to reinvesting profits in local operations, rather than repatriating those profits to Japan. In instances where YKK's fastener-related operations in an overseas market prove to be unsustainable due to insufficient profitability, rather than withdraw from that market YKK will establish some other kind of business, to retain its staff and continue providing employment opportunities for local workers. YKK's commitment applies to workers in local areas in Japan too. YKK calls Kurobe City (Toyoma Prefecture), where the company's mother factory and R&D function are located, its "head temple of technology." Over the years, the company has been moving some headquarter functions from Tokyo to Kurobe.

YKK's executives spend many hours discussing with employees the company's philosophy regarding the "Cycle of goodness," its management principle, "YKK seeks corporate value of higher significance," and its core values. A list of YKK core values includes the following: "Do not fear failure, experience builds success," "Create opportunities for employees," "Insist on quality in everything," and "Build trust, transparency and respect." The last one was added under the founder's direction when the first oil crisis erupted in 1973. He declared: "We will never raise prices opportunistically, even if we lose 10 billion yen." The list of trade-offs below illustrates how much the company is guided by its philosophy and core values, which have influenced the formation of its unique competitive strategy.

YKK was founded in 1934, and has remained unlisted for its entire history. This is because the company's founder, Tadao Yoshida, believing that stocks are a certificate of participation in the business, started up an employee stock ownership plan. This policy has been upheld by his successors, and the company's largest shareholders are its employees.

The founder also wanted employee participation in management. He compared YKK to a forest, made up of various kinds of trees (young and old, tall and short), each must live its own life. He wanted YKK to be a vital organization, in which employees can voice their own opinions, regardless of their positions or specialties.

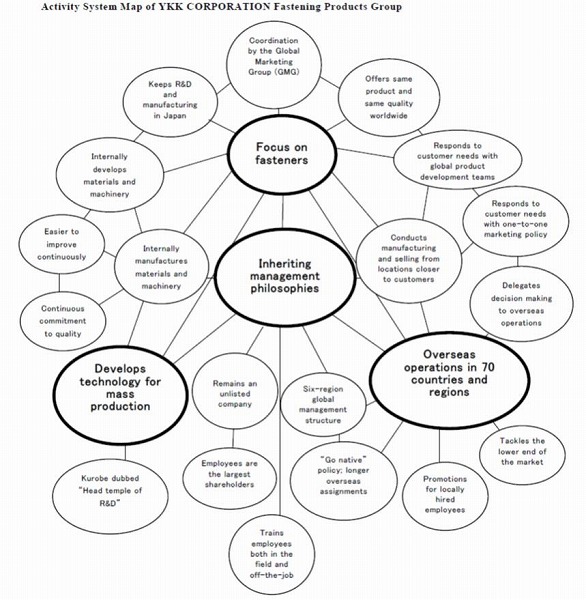

Fit among Activities

In YKK's Fastening Products Group, activities are selected and coordinated in order to simultaneously realize: 1) flexibility for customization; and 2) economies of scale for technological leadership and global service. (Please refer to YKK CORPORATION Fastening Products Group's activity system map, which appears at the end of this report.)

Innovation that Enabled Strategy

- The Global Marketing Group (GMG), which enables YKK to serve global apparel companies. YKK is the only fastening products manufacturer that can provide service on a global basis.

- In 2011, the Analysis Room of the Analysis Technology Center of YKK's Machinery and Engineering Group achieved a first in Japan when it became registered by the U.S. Consumer Product Safety Commission (CPSC) as a Firewall Testing Center that can guarantee the quantity of lead constituent in a product. The Analysis Room, recognized as one of the most reliable testing centers in the world, analyzes YKK's products for both domestic and overseas markets and contributes to YKK's quality assurance system.

- Developed and started selling the "ez-TRAK fastner," which allows insertion from the side as well as from above. Very easy to use for children, the elderly, and people who are wearing gloves(2008).

- Developed and started selling fasteners that open easily and quickly just by pulling the elements to both sides. Eliminates the need to pull down the slider(2012).

Consistency of Strategy over Time

One of the keys to YKK's competitive strategy is its commitment to quality. The company has undertaken vertical integration to achieve better quality. Vertical integration includes R&D, manufacturing and sales, and, especially, the internal development of materials and machinery.

The idea for this strategy occurred to Tadao Yoshida, YKK's founder, during the company's very early history. Yoshida started a business that undertook fastener assembly in 1934. He beban exporting fasteners to India in 1935. There were problems with quality (caused by subcontractors), and faulty fasteners were being returned to the company. This experience made Yoshida realize the importance of quality. To ensure product quality, he began using better materials, internalizing more processes, and investing more in his factories.

In 1947, Yoshida realized that fasteners made in the U.S. under an automated process cost much less than those produced by hand in Japan. These mass-produced fasteners were higher quality and better functioning. Yoshida, who had been trying to sell fasteners for 9 cents, received a counter offer to be a sales agent for an American-made fastener, which sold for 7.40 cents. Seeing the advantages to be gained through mass production, Yoshida committed to the mechanization of operations and the automation of manufacturing. YKK started out with imported machinery, but then found a Japanese machinery manufacturer to develop similar machinery. The new machinery, which was installed in 1951, enabled YKK to achieve both higher quality and lower manufacturing costs, and the company promptly discontinued all handwork. In 1953, the company succeeded in developing a proprietary chain machine and applied for a patent. YKK has been developing machinery internally ever since.

Another key to YKK's competitive strategy is its commitment to manufacturing closer to overseas customers. YKK constructed the company's first overseas factory in New Zealand in 1959, Throughout the 1960s, factoriese were built in Europe and the U.S., where labor costs were much higher than in Japan. The company believed that paying the higher labor costs would be to its benefit, because it could hire qualified engineers who would be responsible for machinery maintenance. From the very beginning, YKK has been consistently choosing to be closer to its overseas customers.

The company plans to increase sales in the lower end of the market by expanding into apparel and sports brands originating in Asia, where higher cost competitiveness will be required. Still, it will continue to apply the same strategy of achieving differentiation by offering the best quality in the class.

The idea for this strategy occurred to Tadao Yoshida, YKK's founder, during the company's very early history. Yoshida started a business that undertook fastener assembly in 1934. He beban exporting fasteners to India in 1935. There were problems with quality (caused by subcontractors), and faulty fasteners were being returned to the company. This experience made Yoshida realize the importance of quality. To ensure product quality, he began using better materials, internalizing more processes, and investing more in his factories.

In 1947, Yoshida realized that fasteners made in the U.S. under an automated process cost much less than those produced by hand in Japan. These mass-produced fasteners were higher quality and better functioning. Yoshida, who had been trying to sell fasteners for 9 cents, received a counter offer to be a sales agent for an American-made fastener, which sold for 7.40 cents. Seeing the advantages to be gained through mass production, Yoshida committed to the mechanization of operations and the automation of manufacturing. YKK started out with imported machinery, but then found a Japanese machinery manufacturer to develop similar machinery. The new machinery, which was installed in 1951, enabled YKK to achieve both higher quality and lower manufacturing costs, and the company promptly discontinued all handwork. In 1953, the company succeeded in developing a proprietary chain machine and applied for a patent. YKK has been developing machinery internally ever since.

Another key to YKK's competitive strategy is its commitment to manufacturing closer to overseas customers. YKK constructed the company's first overseas factory in New Zealand in 1959, Throughout the 1960s, factoriese were built in Europe and the U.S., where labor costs were much higher than in Japan. The company believed that paying the higher labor costs would be to its benefit, because it could hire qualified engineers who would be responsible for machinery maintenance. From the very beginning, YKK has been consistently choosing to be closer to its overseas customers.

The company plans to increase sales in the lower end of the market by expanding into apparel and sports brands originating in Asia, where higher cost competitiveness will be required. Still, it will continue to apply the same strategy of achieving differentiation by offering the best quality in the class.

Trade-offs

- Does not diversify from its founding fastening products business.

- Does not outsource the development and production of fastener manufacturing machinery.

- Does not conduct R&D on core technologies outside of Japan. R&D operations are centralized in Kurobe City (Toyoma Prefecture).

- Does not target the lower end of the market.

- Does not prioritize efficiency or profitability when responding to customer requests. Even if development projects do not result in large volumes or longer product life cycles, those results can be applied to other customers, because of the company's broad product lineup and customer base.

- Does not hesitate to undertake capital investment for the purpose of expanding the number of overseas manufacturing plants. Responding to the needs of overseas customers has always been the priority.

- Does not grow through M&As.

- Does not put cost cutting or scale expansion ahead of quality. Quality must be the priority.

- Does not sell through trading companies or agents. All sales must be conducted through the company's sales units, which are located closer to customers (including customers overseas).

- Does not go public. YKK believes that a stock is a certificate of participation in the business, and only those who participate in the business should own stock. The employees--the company's largest shareholders--are expected to participate in management.

- Does not raise funds through a public offering of stocks. The company raises funds from its employees, who buy the company's stock using part of their salaries and bonuses, through the employee stock ownership plan. Needless to say, employees receive dividends

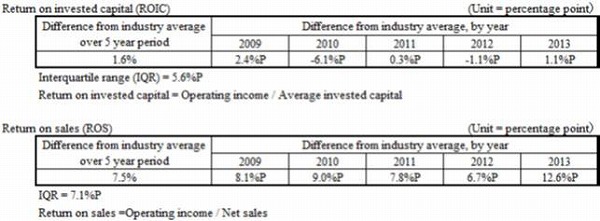

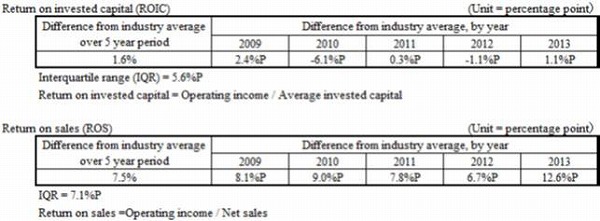

Profitability

Both return on invested capital and return on sales exceed the industry average.

Activity System Map of YKK CORPORATION Fastening Products Group

Winners PDF

- 2014 Porter Prize Winners PDF (All of the award company in this year are published. )