Winners / Selection Rationale

TORIDOLL Holdings Corporation Marugame Seimen Business Unit (Marugame Seimen, Inc.)

The average price per customer is 570 yen (about US$5.42 at 105 yen/$), which is an affordable price. Despite this low price, the Marugame Seimen restaurant places a high priority on providing delicious tasting food that is freshly prepared. All outlets make freshly kneaded udon noodles onsite daily, using only domestic wheat flour. These fresh noodles are made to order (i.e., boiled immediately before serving). The restaurant maintains the high quality of its dashi broth by preparing the broth several times a day (the broth loses both its flavor and aroma as time passes). The restaurant's theater kitchen allows customers to watch the udon noodles being kneaded, stretched, cut, and then boiled. The chain's restaurants have adopted a self-service style, which allows customers to choose their own toppings. This result in a shorter waiting time despite the long lines that form during peak rush times. The restaurant's turnover for seating is also fast.

Established in the year 2000, this restaurant chain has managed to achieve a consistent level of quality in all of its operations, while simultaneously localizing those operations. This has been possible through a combination of employee training, monitoring, and the transfer of authority. The company's Marugame Seimen chain in Japan consists solely of directly operated noodle shops.

Established in the year 2000, this restaurant chain has managed to achieve a consistent level of quality in all of its operations, while simultaneously localizing those operations. This has been possible through a combination of employee training, monitoring, and the transfer of authority. The company's Marugame Seimen chain in Japan consists solely of directly operated noodle shops.(*1) Outside of Japan, Marugame Seimen operates franchise shops under the name "Marugame Udon." Expanding its operations through a combination of company-owned and franchise outlets, Marugame Udon has become the largest Japanese restaurant franchise company in the world. This report focuses on the company's domestic operations.

* This report was written by Professor Emi Osono of Hitsubashi University Business School and Masatomo Ono of TORIDOLL Holdings Corporation, based on: (1) the materials submitted by the winner for Porter Prize screening purposes; (2) interviews conducted by the Porter Prize Organizing Committee; and (3) publicly available information. It is being published with the winner's permission.

Background Information about the Restaurant Industry in Japan

The restaurant industry in Japan, after peaking in 1997, followed a downward trend until bottoming out in 2011. (*2) Since then, the market has continued on a slight upward trend until the outbreak of the Novel Coronavirus (COVID-19) in early 2020. The government responded to the pandemic by requesting everyone to refrain from any non-essential outings.

The overall trend on the demand side shows that several factors have negatively affected the restaurant industry. First, the country's total population has been on the decline since peaking in 2008. There is also the rapid aging of Japan's population to consider. Furthermore, the restaurant industry is vulnerable to economic downturns. There is growing competition from the "home-meal replacement category," which has been gaining momentum as supermarkets and convenience stores increase their lineup of ready-made dishes. Such stores are now offering a wider variety of ready-to-eat food items. Purchasing ready-made meals to eat at home has become an alternative to preparing home-cooked meals. Meanwhile, some positive factors have been supporting the restaurant industry. For example, an economic recovery tends to fuel demand for dining out. Another factor on the demand side has been the strong influx of foreign tourists seen from about 2013 onward. This rise in tourist demand has also contributed to the increased demand for dining out. (*3)

In addition to the challenges on the demand side, the supply side has been under growing pressure from labor shortages (*4) and rising labor costs. Consequently, some 24-hour restaurant chains have closed permanently. At other restaurants, robots have been introduced on a trial basis.

In the restaurant industry, it is difficult to realize the benefits of economies of scale and concentration. This has resulted in a large number of players in this industry. Despite the limited opportunities for achieving economies of scale in the restaurant industry, an increasing number of chains have been gradually expanding their network of restaurants over time. (*5) Many restaurant chains have arranged for cooking to be undertaken at a central kitchen, thereby minimizing the amount of cooking to be done inside the restaurants. Such centralization of cooking operations helps to reduce labor costs at restaurants and maintain a uniform taste.

(*2) Source: Japan Food Service Association, JF Food Service Industry Market Trend Survey, http://www.jfnet.or.jp/data/data_c.html (Last accessed on Nov. 25, 2020.)

(*3) According to the Japan National Tourism Organization, about 32 million foreign tourists visited Japan in 2019. The yearly number of visitors to Japan topped 10 million in 2013, and surpassed the number of Japanese people who went overseas in 2015. https://www.jnto.go.jp/jpn/statistics/visitor_trends/index.html (Last accessed on Nov. 25, 2020.)

(*4) The average ratio of job openings to applicants in 2019 was 1.6, down 0.01 point below the 2018 average (which was the peak), but remained at a high level. Source: Ministry of Health, Labour and Welfare, a press release dated Jan. 31, 2020. https://www.mhlw.go.jp/content/11602000/000594247.pdf (Last accessed on Nov. 25, 2020.)

(*5) The Ministry of Health, Labor and Welfare's Policy Planning Division for Environmental Health and Food Safety, the Research Section of the Pharmaceutical Safety and Environmental Health Bureau, Conditions of the Restaurant Business (General Eating Establishments) and Measures to Improve Their Management (2016). https://www.mhlw.go.jp/file/06-Seisakujouhou-10900000-Kenkoukyoku/0000169249.pdf (Last accessed on Nov. 25, 2020).

Unique Value Proposition

Marugame Seimen is a restaurant chain that serves exclusively Sanuki udon noodles, a type of noodle that originated in Kagawa Prefecture, Shikoku. The menu consists of white udon noodles and complementary toppings like grated ginger, fluffy tempura flakes and green onion, along with a few side dishes. Available side dishes include tempura and a limited selection of rice dishes, such as Omusubi rice balls and Inarizushi (flavored boiled rice wrapped in bean curd). The udon menu offers about 16 udon noodle dishes, such as the traditional Sanuki kamaage udon (warm noodles served in hot water and accompanied by a variety of seasonings and a dipping sauce; kamaage means "straight from the pot" in Japanese); bukkake udon (noodles splashed with a soy-based noodle broth and a few toppings); kake udon (noodles served in a simple dashi broth); curry udon and beef udon (as of November 2020). (*6)

Marugame Seimen's value proposition is characterized by the unique combination of an affordable price, an authentic taste, a lively atmosphere, and speedy service. The restaurant's kamaage udon is priced at 290 yen (US$2.76), and most other noodle dishes range from 300 yen ($2.86) to 400 yen ($3.81). The average price per customer, including toppings, comes to 570 yen ($5.43). Even limited-time menu items featuring premium ingredients are offered in the 600-yen ($5.71) range. This price is lower than the price charged for a comparable meal at a privately owned Udon restaurant, and more on par with the price of lunch at a fast food restaurant.

Despite its low prices, Marugame Seimen's Sanuki udon has an authentic taste. This is the result of the company's commitment to an authentic noodle-making tradition. The ingredients used to make the noodles are domestic flour, water, and salt. That's all. No preservatives or additives are added. Because of the company's commitment to freshly made noodles, all restaurants in the Marugame Seimen chain make the noodles daily from wheat flour.

These restaurants serve only freshly cooked noodles, not ready-made noodles. Each restaurant makes noodles of a consistent quality, paying careful attention to that day's temperature and humidity levels, noting the time it takes for the dough to rest. It takes about 15 minutes to boil Sanuki udon. However, skilled part-time workers, known within the company as "partners," (hereafter "partners") are able to estimate the expected number of customers. The chef boils an adequate amount of udon so that customers can immediately be served freshly cooked udon without having to wait. The freshly boiled noodles are squarely shaped as a result of quadrilateral compression. The noodles are cooked al dente to give Sanuki udon its unique texture: firm, elastic and chewy. The udon is served with soup, made from a dashi broth. The restaurants prepare small batches of the broth several times throughout the day rather than making a large amount at one time. This is because the flavor and the aroma of freshly prepared dashi fade quickly. The side dishes and toppings are also handmade. The tempera is coated with batter in the restaurant kitchen and then deep-fried just before serving to ensure freshness. Omusubi rice balls are made from Japanese rice that is cooked onsite. Omusubi rice balls and tempura can remain on the serving trays in the food service line for only a short time. Serving times for these items are strictly controlled to ensure their freshness.

Marugame Seimen offers customers a sense of actually being in a noodle-making factory. This restaurant provides customers with an experience that engages all five senses. Customers get to eat freshly made udon while enjoying the ambience of a noodle-making factory, filled with steam and heat. At the entrance of the store, bags of flour are piled up, evidence that the restaurant kneads its own dough using 100% domestic wheat flour. The open kitchen has glass walls, allowing customers to watch the chef make the noodles right before their eyes. There is also a proofing cabinet and an original noodle-making machine that mimics traditional methods. These are set up right inside the shop, so that customers can see the noodles being stretched and cut, as the smell of wheat wafts through the air. The boiling process can also be observed. Customers can watch the udon noodles being boiled in a large vat full of steaming hot water and tempura being deep fried. The Omusubi rice balls are also made right in front of customers. They can even watch the side dishes they have ordered being prepared.

Lastly, Marugame Seimen is valued for its speedy service. The company has adopted a cafeteria-style format and a self-service system for the sake of speed. Customers line up at the counter to place an order for an udon dish while helping themselves to side dishes and condiments. Side dishes include tempura and Omusubi rice balls. There are complementary toppings for the udon noodles, such as tenkasu (crunchy bits of deep-fried tempura batter), chopped green onions, and grated ginger. Customers can freely help themselves to these toppings. The menu usually offers a wide selection of other toppings and side dishes, which include rice dishes. Customers are able to view the available side dishes and make a selection, placing the items they want on their tray. This process is much more efficient than sit-down restaurants, where orders are taken and the food is served at the table. Even when there is a line at the counter the wait time is far shorter, because the orders are being filled much faster.

Marugame Seimen attracts a broad range of customers. People working at an office nearby a Margame Seimen noodle shop are drawn to the shop during their lunch break because they know that they can get a quick meal there. The company's restaurants in the suburbs cater to families with children and the elderly. Another reason why the restaurant is popular with men and women of all ages is that its customers can choose the amount of udon noodles and toppings they want to eat.

(*6) Marugame Seimen's website: https://www.marugame-seimen.com/menu/ (Last accessed on Nov. 25, 2020.)

Unique Value Chain

The unique features of Marugame Seimen's value chain are its store operations, training program, and store development.

◆ Product developmentThe firm develops and sells limited-time menu items, using seasonal ingredients in a 45-day cycle, thereby attracting new customers and encouraging repeat customers to visit its restaurants.

Marugame Seimen's overseas outlets adjust their dishes to suit local tastes and follow local food customs. These outlets adjust the thickness, the flavor, and the temperature of the dashi broth to suit the preferences of local customers. For example, pork bone soup is used in the United States. In Thailand, tom yam soup is used, along with bok choi and chili peppers. The company develops localized menus to win support from local consumers while maintaining the authenticity of Japanese Sanuki udon dishes.

◆ ProcurementMarugame Seimen can procure high-quality ingredients at low cost because TORIDOLL Holdings is able to purchase the ingredients in bulk. These ingredients are used by all of its group companies. It is important to remember that udon is made using only flour, water, and salt. Marugame Seimen is extremely selective about its ingredients, to ensure that all of the ingredients are safe and reliable. Wheat flour, in particular, is the key ingredient that defines the taste of udon. For this reason, the restaurant uses 100% Japanese wheat. The company has arranged for a stable supply of domestic wheat, and is able to procure it cheaply by buying in bulk.

◆ Store developmentSince its earliest days, Marugame Seimen has remained committed to building a chain of directly operated restaurants in Japan. The company takes special care in the development of each restaurant. The Marugame Seimen Business Unit shares its corporate vision with the restaurant staff, and helps them hone their udon-making skills.

Marugame Seimen got its start by successfully launching a restaurant outlet in the food court of a shopping mall. Since then, it has been expanding its restaurant business, primarily by opening roadside noodle shops in the suburbs. In recent years, the company has been opening small-format shops in the foot traffic areas of large cities. But first Marugame Seimen had to create a more compact kitchen space. The monthly sales per store for its urban noodle shops is about 1.3 times higher than monthly sales at its roadside noodle shops in the suburbs, and profits remain at a high level.

◆ Store operationsMarugame Seimen's store operations fall into two categories: cooking operations conducted inside the restaurant, and the quality management procedures implemented by the noodle shops and the headquarters.

In order to recreate a Sanuki udon noodle-making workspace, each kitchen is equipped with a noodle-making machine and a large boiler. The open kitchen format helps to engage the five senses. Customers have a clear view of the counter where the noodles are being kneaded, stretched and cut. They can see steam rising from the boiler. They can smell the wheat, and hear the tempura batter sizzling in the deep fryer. After customers have stood in line and placed their udon orders, they move forward in the line and watch the udon orders being filled. It gives them the sense of being in a real noodle-making factory. Moreover, the fresh dashi is prepared numerous times a day at each Marugame Seimen restaurant.

The person in charge of noodle making will conduct inspections to confirm that the proper procedures are being followed in all parts of the food preparation process as part of the quality control monitoring being undertaken at every restaurant on a daily basis. Each restaurant must make slight adjustments to accommodate any changes in temperature or humidity levels, then check on the condition of the noodles, and confirm that the noodles are being boiled for the optimum length of time. Instead of trying to make the food taste the same from shop to shop without any variation, the noodle makers are instead encouraged to create their own signature taste. It is as important as making sure the noodles are handmade, and that the fresh noodles are served immediately.

The quality of the food, the service, and kitchen hygiene are checked every few hours. Partners must have their temperatures taken, and the inside of the refrigerator is regularly inspected. There is also a system for controlling the temperature of the broth. In addition, several cameras have been set up inside each restaurant. A dedicated team of specialists are responsible for remotely monitoring operations. In this way, the headquarters can stay abreast of developments regarding the situation at a specific restaurant. Also, the master udon craftsman makes periodic visits to restaurants and confirms that quality standards are being met. Furthermore, many of the back office's administrative duties can be executed using a tablet.

◆ MarketingAll of the Marugame Seimen restaurants make the udon noodles from scratch, using wheat flour. The restaurant chain is known for immediately cooking and serving freshly made noodles. The company invests in marketing to continually raise awareness of the superior value that its restaurants provide. Beginning in January 2019, the company's TV commercials featured two catchphrases: "At all of our shops, we start with flour," and "Our udon is alive!" With these catchphrases, the company effectively communicates the message that the overall taste of Marugame Seimen's artisan udon reaches a whole other level. As a result of these TV commercials, the brand recognition rate increased 5% from the previous year, rising from 86.5% to 91.9%, and repeat customers (light users) who visit the restaurants once a month increased 15% year on year.

◆ Human resource managementAt Marugame Seimen, restaurant employees are middle-aged or older. Compared with students hired as part-time employees, who will likely leave after a few years because of graduation or some other reason, somewhat older employees tend to remain at the same job for a long time. Especially in the case of homemakers who cook on a regular basis, they can pick up the techniques in a relatively short period of time. In addition, homemakers tend to be knowledgeable about local seasonal ingredients and cooking methods. They are able to propose menu items that include local ingredients, like burdock root tempura and goya karaage (fried bitter gourd). Occasionally, such proposed items will be incorporated into the menu. Moreover, homemakers are well informed about local affairs and are able to help with predicting the number of customers who will be visiting the restaurant. Marugame Seimen has created the type of workplace that welcomes feedback and suggestions from the employees on the frontline. This brings them satisfaction, knowing that they are contributing to the store's operations, and motivates them to continue working at the restaurant for many years.

A manual has been developed, explaining every step of the work process. With this manual even a person without any experience would be able to prepare the food and serve customers. This approach makes it possible to learn all aspects of restaurant operation in a very short time. The manual explains everything very clearly, starting with the most basic parts of the job. For example, how to open a bag of wheat flour, and what to do with the empty bag of flour. At the same time, the manual is not overly detailed. In principle, employees are basically expected to think for themselves and take action. They must be able to adapt to the circumstances of the customer that is right in front of them. In order to do this, they must be able to demonstrate some originality and ingenuity.

In order to train the employees who works at Marugame Seimen chain restaurants, the company uses an educational tool called a "ClipLine." (*7) This is how staff members receive their individual assignments. Instructional videos are also made available to the staff through this tool. The details of work assignments are clearly spelled out in the manual. However, some details are difficult to learn just by reading instructions. Videos help to further employees' understanding of such details. For example, training videos show how to drain the cooked noodles and shake off the water. The placement of equipment in the kitchen workspace is also explained. This approach significantly reduces the amount of time required for employee training.

Marugame Seimen has created a skill certification program for certifying its udon craftsmen. This program not only helps chefs to upgrade their skills, but also creates a system for turning out professional-level makers of artisan noodles. Moreover, this program helps to raise the motivation of people working in the company's restaurants. Individuals who complete the udon craftsmen training program must pass an examination, during which their noodle-making techniques and knowledge are tested, to become a certified udon craftsman. These individuals have cultivated a first-hand knowledge of flour, water and salt. They understand the mechanism by which delicious udon is created. They develop a sense of how the hands of the artisan work the dough, a skill that is indispensable for making udon. They need to know how to finish off noodles that have been under boiled or over boiled. They basically have to cultivate an in-depth understanding, as well as expertise in all aspects of udon noodle making. Because udon is made from such simple ingredients (flour, water and salt), the taste of the finished noodles can be affected by the ambient temperature and the humidity. Therefore, it is necessary to make adjustments to the amounts of flour, water and salt used, taking into account the ambient temperature and the level of humidity in the air. Considering the delicate nature of the noodles, it is not surprising that the noodles will taste different from restaurant to restaurant. The udon craftsmen training program was established to reduce differences in flavor and produce a tasty Sanuki udon noodle. In each branch store the udon craftsman's name appears on a sign that is prominently displayed. Chefs are certified using a starred ranking system (one to four stars). Currently, there are 410 one-star chefs, 1 two-star chef, no three-star chefs and no four-star chefs (as of September 2020). The certified chefs wear a blue-and-white top, a blue hat, and a blue apron. (The other chefs wear white uniforms.)

At Marugame Seimen, the most highly skilled udon craftsman is the master udon craftsman. So far, only one person has become a master udon craftsman, and this person has made every effort since the restaurant's earliest days to ensure that the udon noodles continue to meet Marugame Seimen's extremely high expectations regarding taste. The master udon craftsman visits every store in Marugame Seimen's nationwide chain, and ensures that the udon, tempura and rice dishes meet taste and quality standards. Furthermore, the master udon craftsman trains the other chefs, helping them to cultivate an acute sense of taste and develop a delicate palate for udon, so that they can recognize and reproduce the precise taste of Marugame Seimen udon noodles. The master udon craftsman upholds the authentic taste of Marugame Siemen noodles by examining a cross-section to make sure that the noodles are not perfectly square, but rather densely compressed and slightly twisted strands. The master udon craftsman confirms that the noodles are all the same thickness, and that the noodles meet all the requirements. If there is any inconsistency regarding the thickness of the noodles, the temperature of the cooking water must be adjusted. It is also important to confirm that the noodles are being rinsed properly, and that there is just the right amount of chewiness. Such points are on the master udon craftsman's checklist, and each item must be checked carefully, one by one.

(*7) ClipLine is a video-based educational tool developed and offered by a Japanese startup company, ClipLine Inc., https://corp.clipline.com/ (Last accessed on Nov. 25, 2020.)

◆ Firm infrastructure (equipment investment)As part of measures taken to reduce the environmental load and conserve energy, it is necessary to make sure that the large boiler is working properly, and that adjustments are being made to control the salinity concentration. (The company's data regarding such details is based on the feedback of seasoned udon craftsmen.) Next, an IoT-equipped boiler was developed. By automating the cooking process in this way, Marugame Seimen has been able to reduce the electricity and the amount of water used. The introduction of a type of wringer used to separate out the frying dregs makes it possible to reuse the cooking oil. In addition, a filtration device for the oil has been installed, enabling a lengthening of the replacement cycle. All this equipment has made the work procedures for cleaning more efficient, and has helped to improve kitchen safety by preventing burns and scalds.

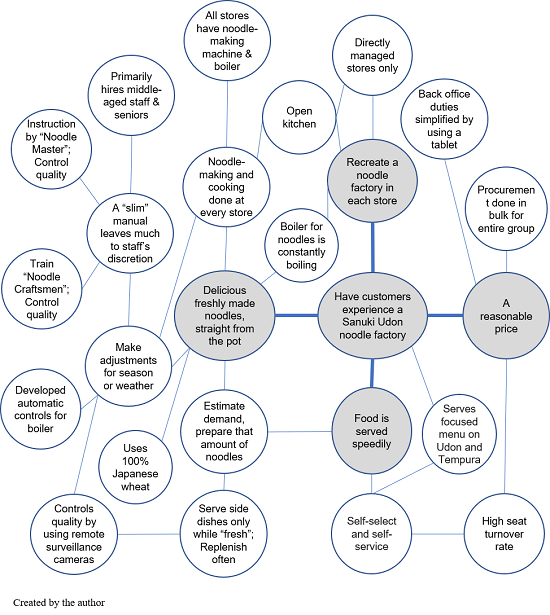

Fit among Activities

Marugame Seimen's activities are perfectly optimized, in order to recreate for customers the experience of eating udon at a Sanuki udon noodle factory. Specifically, the company provides the following value: (1) freshly made udon; (2) available at an affordable price; and (3) without any waiting.

In order to provide freshly made noodles, Marugame Seimen has decided to make the udon noodles at each restaurant, and cook the noodles immediately before serving. Moreover, the company has chosen an open kitchen style to better communicate the value of homemade noodles to its customers. This is reinforced by the store's physical presence, another value that the company provides and one that is directly linked to the main value proposition. The store's "presence" is, specifically, the aroma of the wheat, the steam that rises from the vat of boiling udon, and the sound of tempura frying.

The streamlined menu features udon and some side dishes, including tempura, Omusubi rice balls and Inarizushi (flavored boiled rice wrapped in bean curd). The limited menu means that customers will spend less time trying to decide what to order. Consequently, customers can pass through the order line quickly, thereby reducing the wait time. At the same time, the company has streamlined its cooking process by intentionally limiting the variety of ingredients and simplified kitchen operations to avoid unnecessary complications. As a result, the company's employees are able to master their kitchen duties more quickly while simultaneously making it easier to ensure the quality of operations and control costs. (Please refer to the activity system map for TORIDOLL Holdings Corporation's Marugame Seimen Business Unit (Marugame Seimen, Inc.). The activity system map appears at the end of this report.)

Innovation that Enabled Strategy

- Although centralized kitchens have become a common feature in the chain restaurant industry, each Marugame Seimen branch makes the udon from scratch, swiftly serving the freshly boiled udon noodles straight from the pot, and offers these authentic noodle dishes at an affordable price, which is the company's value proposition.

- Each branch store is committed to providing high-quality food. To ensure that quality standards are being met, several surveillance cameras have been installed in every store, and a specialized team at the headquarters monitors the operations at chain stores. The individuals responsible for monitoring store operations confirm the actual situation in each store by viewing several cameras, and immediately give the restaurant staff instructions when required. In this way, a system has been devised that allows for adjustments to be made in real time. Some examples of the items on the headquarters' checklist: (1) Are procedures being implemented in the precise order required for each assigned task? (2) Do any of the tempura dishes being displayed contain more pieces of tempura than the amount specified? (3) Is the machinery operating properly? (4) Are POP displays, advertisements and other signage positioned correctly and in the right place?

- Developed a way to predict the level of demand at each store, because the boiled udon noodles must be served straight from the pot.

- Established certification systems for certifying udon craftsmen and master udon craftsmen.

- ? Developed a large boiler with automatic controls. This is to minimize differences in quality between stores, reduce the burden on individual stores, and simultaneously conserve energy. With regard to the 2019 Energy Conservation Grand Prize Awards, TORIDOLL won the Ministry of Economic Trade and Industry Prize (the METI Minister's Prize) in the Grand Prize Awards for Excellence in Energy Efficiency and Conservation program. These awards are sponsored by the Energy Conservation Center, Japan (ECCJ), and TORIDOLL won in the Energy-saving Activities Category for outstanding initiatives in businesses or workplaces. The company was awarded this highest honor for large energy savings in the making of udon noodles. In the past, the task of controlling the large boiler, to ensure proper boiling and salinity levels during the udon cooking process, was up to the employees, and depended largely on the amount of experience they had. Waste abounded, with too much hot water and electricity being used. Moreover, there was excessive water boiling and heat dissipation. An automatic boiler was developed jointly by Chubu Electric Power Company, Nichiwa Electric Corporation, and Marugame Seimen, Inc. Through this project, the employees' expertise was turned into data. For example, it became possible to control the heater's output, which automatically responds to changes in temperature. The boiler also automatically fills up with a predetermined optimal amount of water. In trials conducted at specially selected stores, the amount of electricity used was cut by 31.3%, while water usage was reduced by 47.6%.

Trade-offs

- Does not use a central kitchen. Does not pursue economies of scale by centralizing operations at a central kitchen. Marugame Seimen puts a priority on serving udon noodles straight from the pot. By having chosen a decentralized approach, the company accepts that the same cooking process must be conducted at every store, and that redundant cooking procedures are unavoidable. At the same time, a decentralized approach is more costly than a centralized approach, when considering the personnel costs and the necessary training expenses. Also, every store must be equipped with a noodle-making machine, which translates into higher initial costs. Moreover, the large boiler is usually in operation during the store's operating hours. This means that Marugame Seimen noodle shops will have much higher utility expenses than other restaurants. As for store space, it is necessary to allocate a larger amount of space for the kitchen, even though it does not contribute directly to revenues.

- Does not adopt a strategy in which a high concentration of branches in a specified territory is pursued. Marugame Seimen does not operate a central kitchen. Thus, there is no need to open numerous branches in close proximity to a central kitchen (a pattern of store expansion characteristic to the Dominant Strategy of chain store expansion, in which one chain monopolizes a given sales territory by establishing an overwhelming physical presence).

- Does not expand its domestic restaurant chain by franchising. The adoption of a franchise format would contribute to lower store opening costs and procurement costs. However, Marugame Seimen prefers to operate a chain of directly managed stores. The advantages of directly managed stores are: (1) Successfully achieving the widespread adoption of the company philosophy and compliance with management's instructions; (2) reinforcing a commitment to quality as the highest priority; (3) and gaining employees' cooperation with regard to correctly and thoroughly mastering the techniques involved.

- Does not use imported wheat. Although imported wheat is easy to make into noodles and those noodles will keep their shape, Marugame Seimen wants customers to be able to enjoy the strong aroma of the wheat. It is for this reason that the company uses domestically produced wheat. It should be noted that although Japanese wheat is valued for its strong aroma, it requires a higher level of skill when used in noodle making.

- Does not make the noodles in advance. It would be much cheaper to let branch stores cook frozen or chilled noodles prepared at a central kitchen that only had to be boiled. However, Marugame Seimen takes pride in its noodles, which have a firm, "al dente" texture and an authentic taste that can only be found in freshly made noodles served straight from the pot.

- ? Does not wait for a customer order to boil the noodles. It takes 10 - 15 minutes to boil the noodles. To minimize the customers' wait time, the company predicts the number of customers who will be visiting the store at any given time, and will start preparing the noodles in advance. That way, when customers enter the store, noodles will already be cooking in the boiler. This practice of boiling noodles prior to receiving an actual order reduces the customers' wait time while simultaneously giving them the chance to experience the authentic taste of freshly made noodles served "straight from the pot."

- Does not focus primarily on young recruits when hiring store staff. Marugame Seimen will hire people of any age − young or old, male or female.

Consistency of Strategy over Time

Marugame Seimen was established in November 2000, and the first shop was opened that same month in Kakogawa, Hyogo Prefecture. In his childhood, TORIDOLL Holdings Company founder Takaya Awata visited several noodle-making factories in Kagawa Prefecture. From the very beginning, it was Mr. Awata's desire to have his customers experience for themselves a restaurant where the Sanuki udon noodles are being made from scratch right before their eyes and served straight from the pot.

Mr. Awata explains the reason why people from all over Japan are willing to travel to udon noodle-making factories. He says that people come for the experience. People can eat udon that has been kneaded and boiled right in front of them. There is value in that scene, combined with that unique experience. Not only are the udon noodles delicious, the udon dishes are available at an affordable price, and the service is good. Mr. Awata thinks the reason that customers come to Marugame Seimen restaurants is that all these pieces are in place, in other words, they get "the complete package." He firmly believed that if the ambience of an authentic noodle-making factory could be recreated, customers would surely come to the restaurant. He made the decision to provide noodles that were "freshly made and served straight from the pot" no matter what. This was his unwavering conviction. That's how Marugame Seimen was born.

In the early days, Marugame Seimen restaurants were primarily opened at food courts in shopping malls. Freshly made noodles served straight from the pot attracted many customers. By setting up a shop inside a food court, the company could reach customers who had come to the shopping mall. Moreover, it would cost less to open a shop in a food court than it would to open a restaurant. When considering that the recognition of the Marugame Seimen name was low, the food court option was deemed the correct choice at that time. The company next opened a roadside restaurant in the suburbs. There was enough space in which to set up a large open kitchen. This became the store layout that we see today. After that, the company began opening smaller stores in places with high foot traffic, primarily near offices and train stations. The company also streamlined the number of items on the menu. This made it possible for the company to continue offering freshly made udon noodles straight from the pot even in a smaller kitchen.

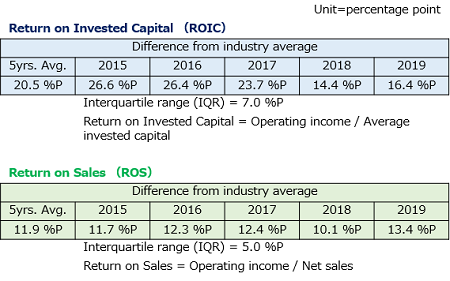

Profitability

TORIDOLL Holdings Corporation's Marugame Seimen Business Unit (Marugame Seimen, Inc.) saw its five-year averages for return on invested capital (ROIC) and the return on sales (ROS) widely exceed the industry average. (Profitability analysis was conducted by PwC Japan.)

Activity System Map of TORIDOLL Holdings Corporation's Marugame Seimen Business Unit (Marugame Seimen, Inc.)

Winners PDF

- 2020 Winners Pdf (All of the award company in this year are published. )